Pump Problems: NPSH

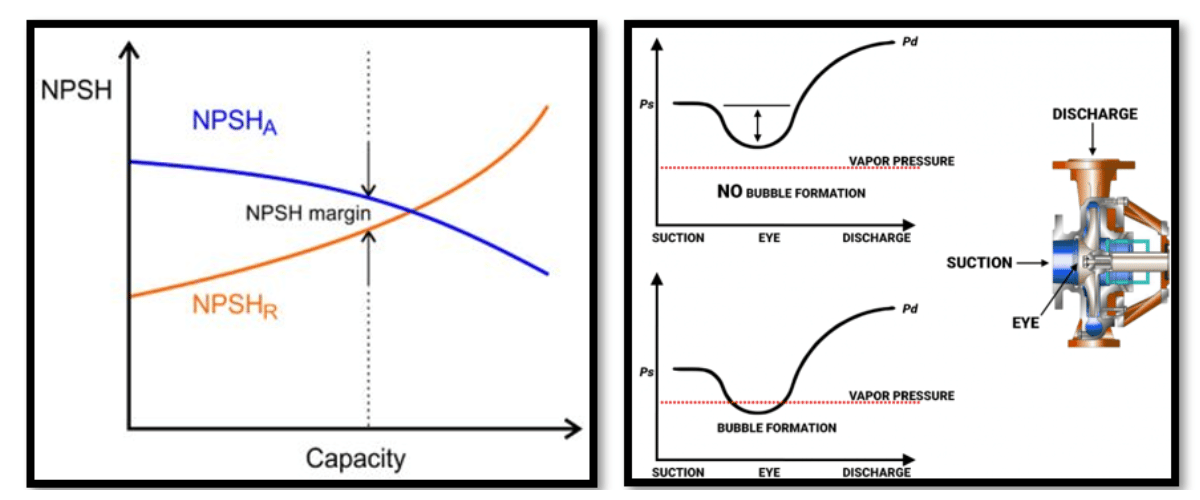

Net Positive Suction Head (NPSH) is a critical parameter in the operation and design of pump systems. It is essentially a measure of the pressure at the suction port of a pump. This pressure is crucial for ensuring that the pump operates efficiently and without causing damage to itself or the system it is part of.

- NPSHA (Net Positive Suction Head Available): This is a property of the pumping system, calculated by the system designer. It represents the pressure at the suction side of the pump and is influenced by factors such as the absolute pressure on the liquid's surface in the reservoir, the vertical distance between the reservoir and the pump, friction losses in the suction piping, and the liquid's vapor pressure.

- NPSHR (Net Positive Suction Head Required): This is a property of the pump itself, determined by the manufacturer. NPSHR represents the minimum pressure required to avoid cavitation—the point where vapor bubbles form and then collapse, causing damage to the pump.

For a pump system to operate without cavitating, NPSHA must always be greater than NPSHR.

To calculate NPSHA, use the formula:

NPSHA = Ha ± Hz - Hf + Hv - Hvp

Where:

- Ha = The absolute pressure on the surface of the liquid in the supply reservoir.

- Hz = The vertical distance between the surface of the liquid in the supply reservoir and the centerline of the pump (positive if above the pump, negative if below).

- Hf = Friction losses in the suction piping.

- Hv = Velocity head at the pump suction port.

- Hvp = Absolute vapor pressure of the liquid at the pumping temperature.

It’s commonly said that a pump “sucks” water. In reality, pumps create low pressure at the inlet, allowing atmospheric or head pressure to force liquid into the pump. Understanding this pressure differential is key to designing effective pump systems and avoiding issues such as cavitation.

When NPSHA is lower than NPSHR, cavitation occurs. Cavitation is the formation of vapor bubbles in the pump when the local pressure falls below the liquid's vapor pressure. These bubbles collapse, causing damage to the pump impeller and housing, which significantly reduces the pump's lifespan.

Conversely, if NPSHA is excessively high, it can cause unwanted flow-through or exceed the casing pressure rating, leading to potential damage.

Here are strategies to address and improve NPSH-related issues:

1. Maintain Adequate Liquid Levels: If cavitation occurs as the supply reservoir empties, ensure a higher level of liquid remains in the reservoir.

2. Adjust Pump and Tank Positions: While raising the tank or lowering the pump may not always be feasible, these adjustments can provide additional suction head.

3. Reduce Friction Losses: This can often be the simplest modification. Options include increasing the suction pipe size, decreasing the suction pipe length, and removing obstacles like valves, strainers, and elbows. Replacing old, corroded, or blocked pipes can also help.

4. Control Temperature: Minimize vapor pressure spikes by controlling the temperature of the pipes. Use insulation or light-colored paints in areas exposed to high sun or thermal heat.

5. External Pressure: Though atmospheric pressure is beyond control, one solution might be to stage feed the pump with another pump to boost pressure.

6. System Design: Engage a reputable and qualified pump engineer during the initial design phase of the pump system. Proper design and selection of pumps based on NPSH considerations can prevent many operational issues.

NPSH is a fundamental concept in pump operation, and understanding the differences between NPSHA and NPSHR is vital for ensuring pump longevity and efficiency. By addressing potential NPSH-related issues through thoughtful design and practical adjustments, you can avoid cavitation and other detrimental effects, thereby maintaining optimal performance in your pump systems.

By keeping a keen eye on NPSH parameters and incorporating best practices in system design, you can significantly improve the reliability and efficiency of your pumping applications. Whether you’re dealing with industrial processes or simple water systems, attention to NPSH is crucial for smooth and trouble-free operation.

Call us on (02) 4271 2220

email us here or complete the order form below