Delivering Key Pumping Solutions for a National Mining Client’s Coal Stockpile Project

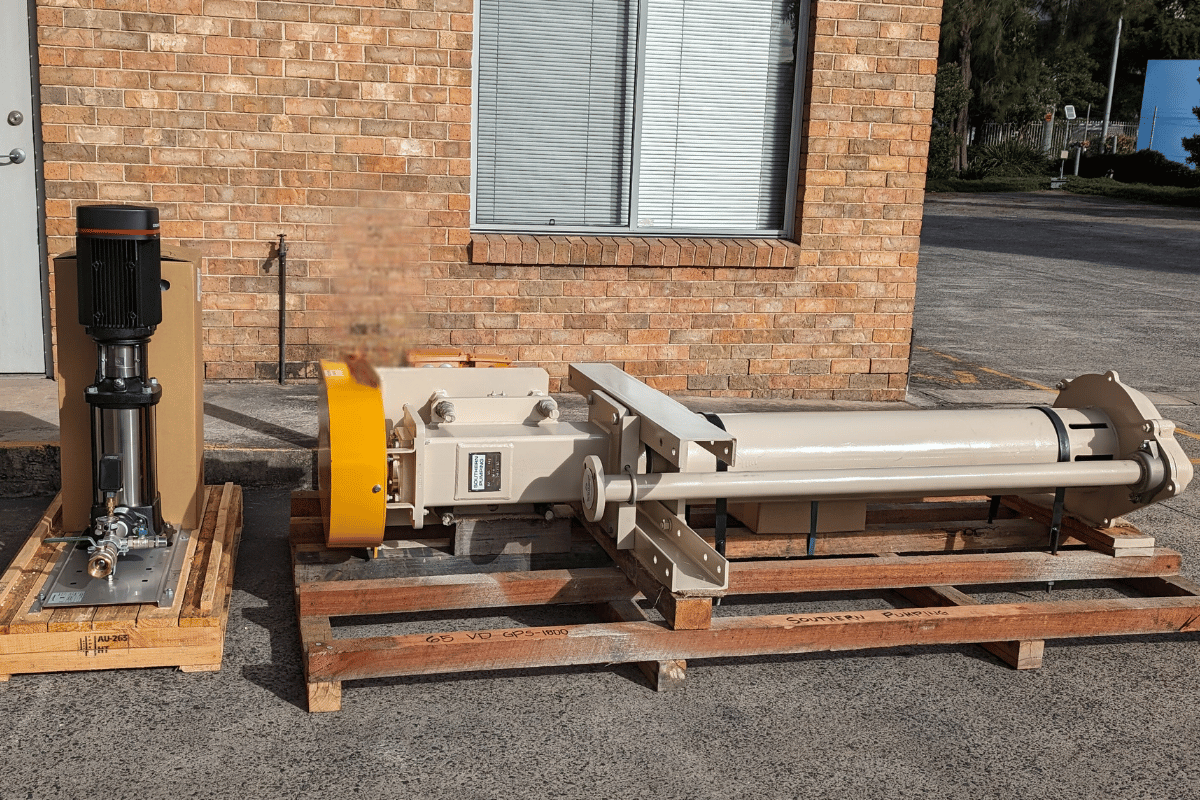

Southern Pumping has successfully delivered two critical pumps for a national mining client’s Coal Stockpile. These pumps, designed for specific applications within the project, address unique operational needs and improve overall efficiency. Below is a detailed account of the pump specifications and how Southern Pumping met the client's requirements.

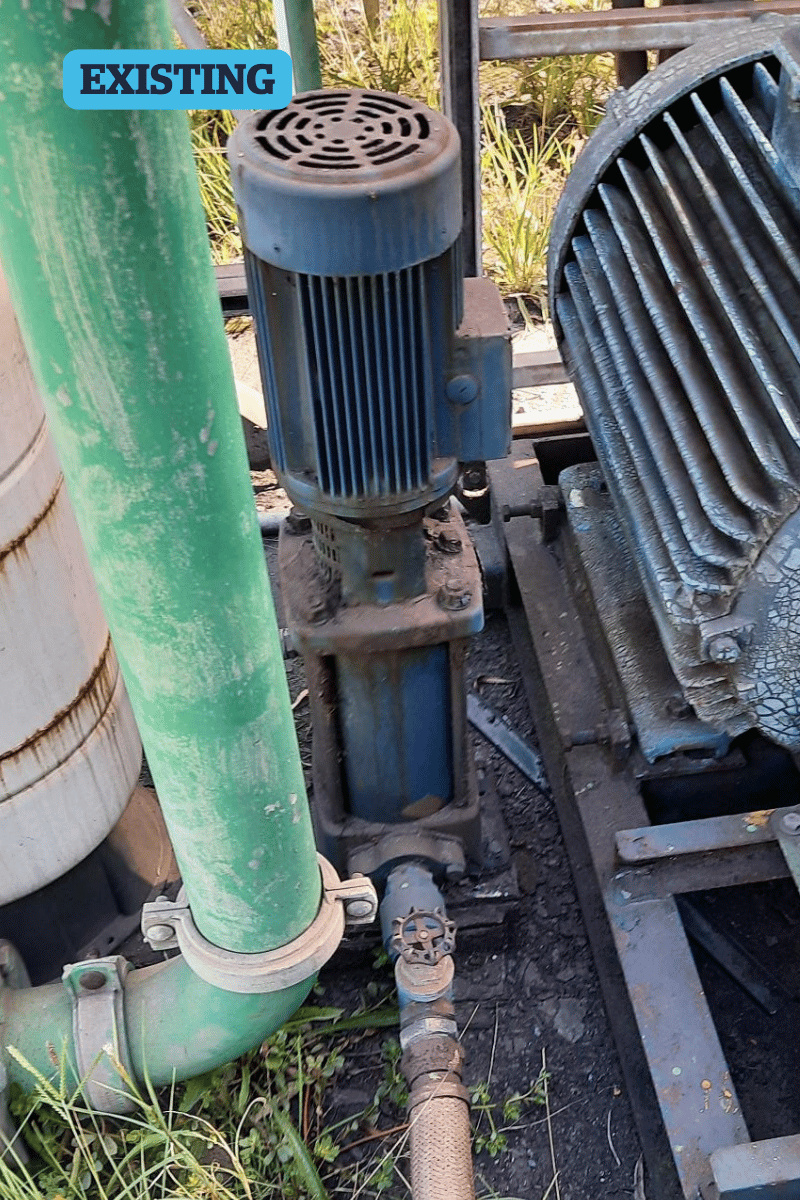

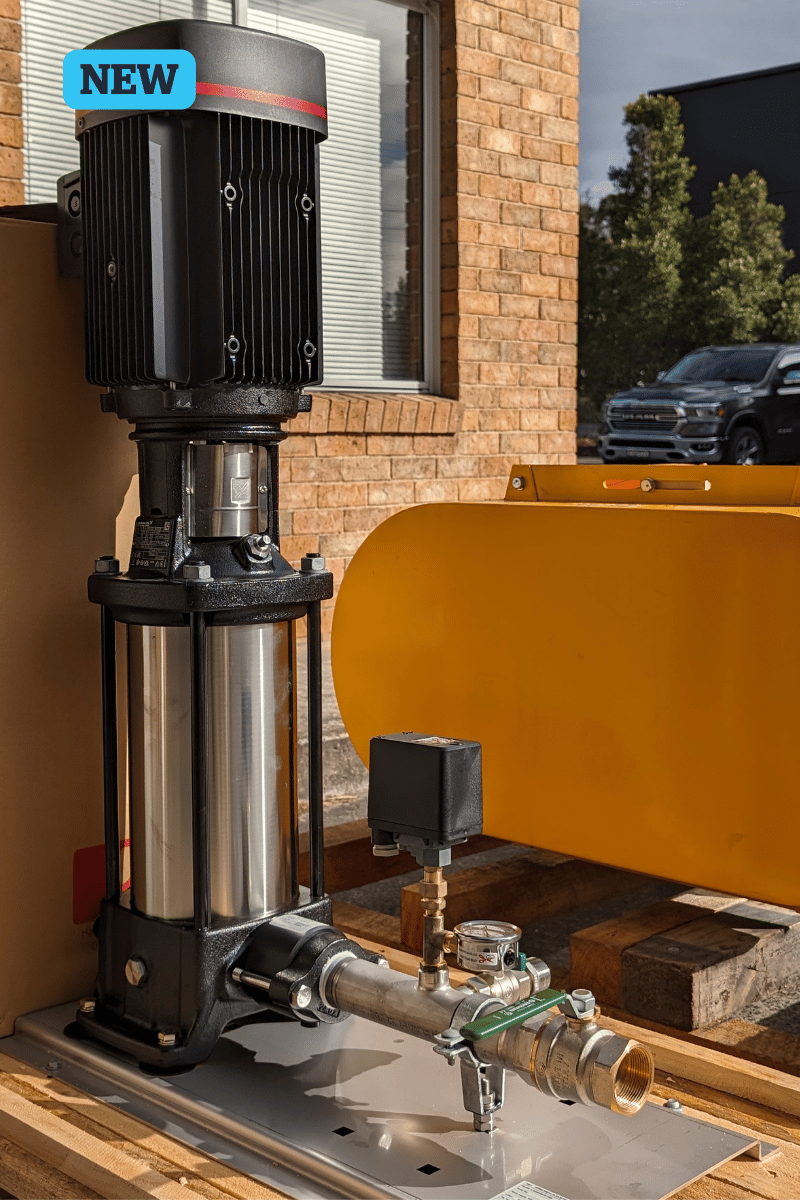

The upgraded jacking pump is designed to maintain line pressure on a spray manifold to avoid water hammer and provide water flow for a truck wash make-up.

- Outlet Pressure: 800 kPa (existing system controls to 790 kPa)

- Flow Rate: Minimum of 10 m³/hr to handle truck wash water make-up

- Water Type: Rainwater with some coal fines, passed through a settling basin (TSS approx. 200 mg/L)

- Inlet and Outlet: Existing pump has a 40 NB inlet and outlet, with connected pipework of 50 NB

Southern Pumping selected the Hydro Solo-S CR10-10 Jacking Pump Set, an advanced and reliable pump that meets all specified requirements. The Hydro Solo-S CR10-10 ensures a stable outlet pressure of 800 kPa and a flow rate exceeding 10 m³/hr, perfectly accommodating the truck wash needs. This pump is capable of handling the rainwater with coal fines efficiently, ensuring smooth operation. Additionally, the Hydro Solo-S CR10-10 integrates seamlessly with the existing 50 NB pipework, minimizing installation adjustments and ensuring a straightforward transition from the previous system.

To periodically remove water from the truck wash settling basin to maintain water quality by preventing pH levels from rising too high.

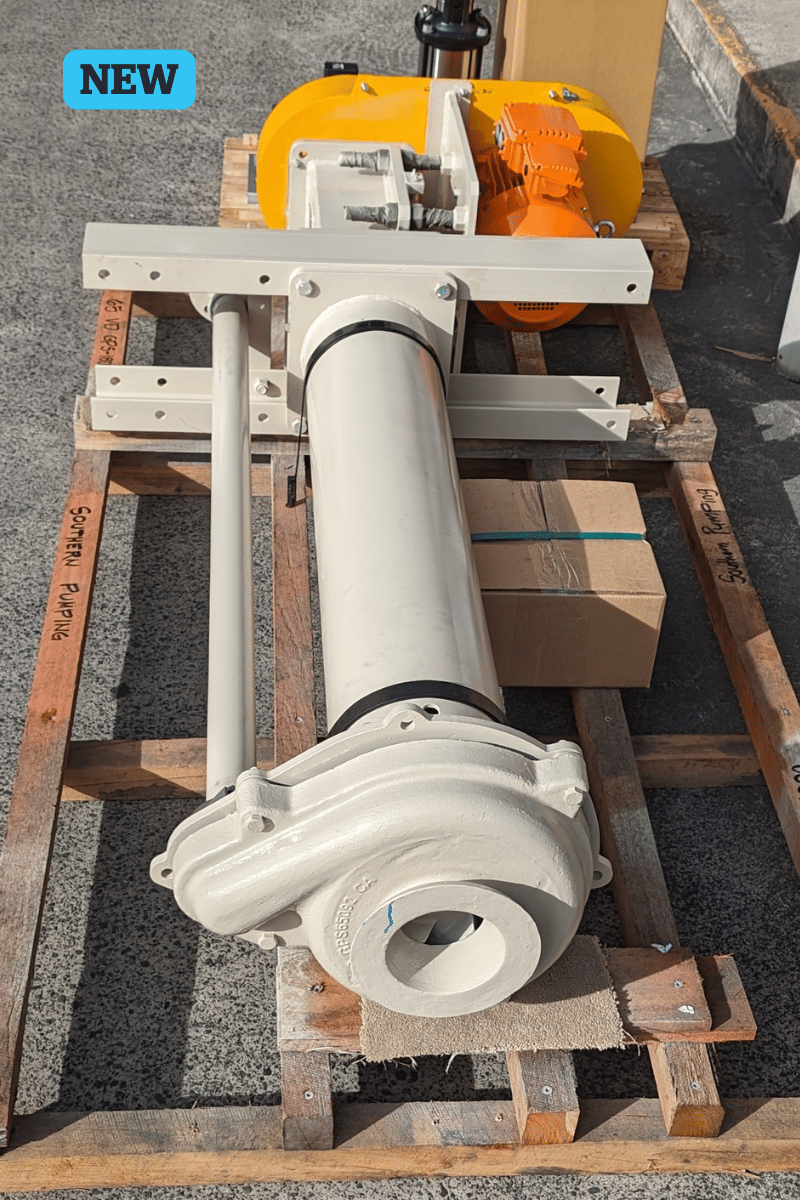

- Pump Type: Submersible slurry pump with a motor

- Pumping Requirement: 3 m upward lift and approximately 15 m horizontal discharge to a drain

- Sump Depth: 2.4 m, with the motor ideally positioned above the water level

- Flow Rate: Flexible; estimated at around 108 m³/hr based on existing pump performance

- Inlet/Outlet Size: 65 NB

- Water Type: Generally clean water with potential fine coal slurry

Southern Pumping provided the 65 VD GPS - 1800 Cantilever Sump Pump, which matches the 65 NB inlet and outlet size, ensuring continuity and reliability in the system. The 65 VD GPS - 1800 Cantilever Sump Pump is designed to handle fine coal slurry without blockages, maintaining efficiency in the system. This pump is capable of the required 3 m lift and 15 m horizontal discharge effortlessly, and the cantilever design ensures that the motor remains above the water level, providing optimal performance and longevity. The adaptable mounting solution ensures the pump fits perfectly within the newly constructed pump well.

By delivering these two high-performance pumps, Southern Pumping has reinforced its commitment to providing tailored solutions that meet the specific needs of industrial clients like this national mining client. The jacking pump upgrade ensures seamless operation and water hammer prevention, while the submersible slurry pump effectively manages water quality in the truck wash settling basin. These enhancements not only improve operational efficiency but also contribute to the longevity and reliability of the infrastructure of the client’s project.

Call us on (02) 4271 2220

email us here or complete the order form below