News & Articles

W

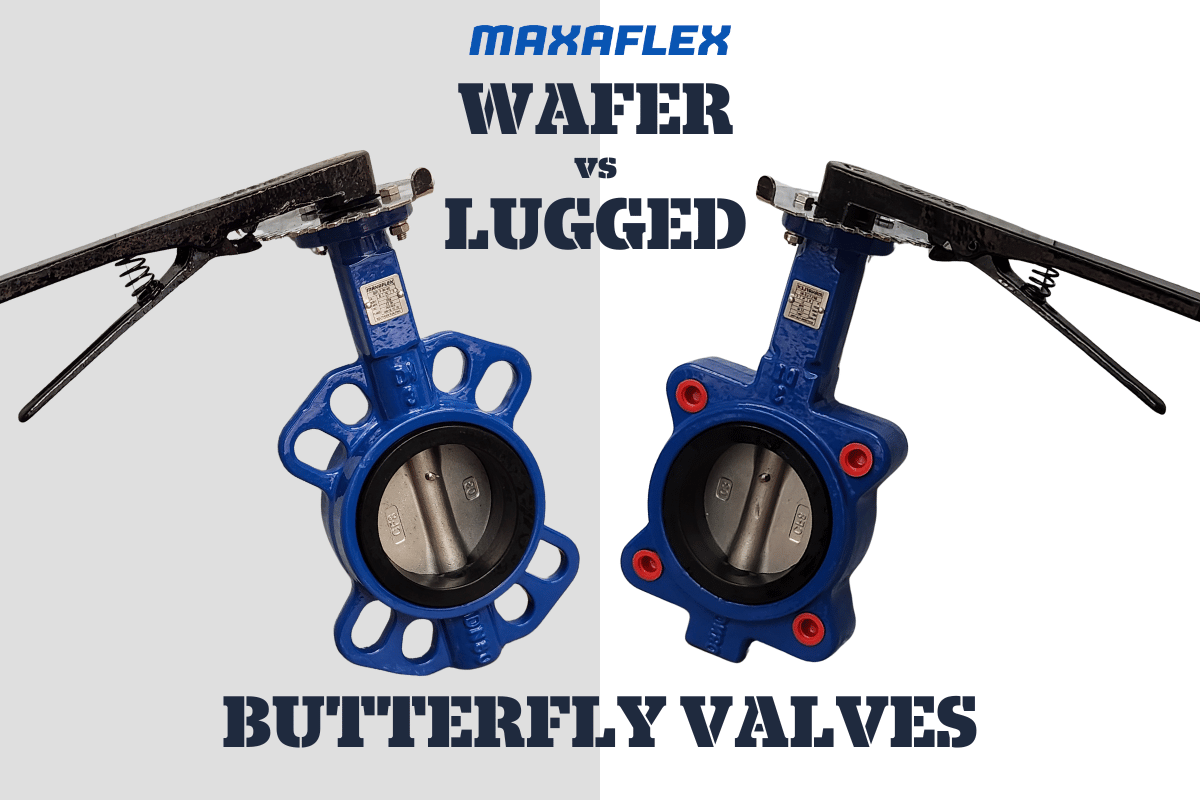

Exploring the Benefits and Functions of Pressure Tanks on Water Pump<span class="fr-marker" data-id="0" data-type="true" style="display: none; line-height: 0;"></span><span class="fr-marker" data-id="0" data-type="false" style="display: none; line-height: 0;"></span<span class="fr-marker" data-id="0" data-type="true" style="display: none; line-height: 0;"></span><span class="fr-marker" data-id="0" data-type="false" style="display: none; line-height: 0;"></span<span class="fr-marker" data-id="0" data-type="true" style="display: none; line-height: 0;"></span><span class="fr-marker" data-id="0" data-type="false" style="display: none; line-height: 0;"></span>hen choosing a butterfly valve, you’ll often come across two main types: lugged and wafer butterfly valves. While they serve the same basic function, they have key differences that can impact performance, installation, and cost. Let’s break it down in simple terms so you can decide which one fits your needs best.

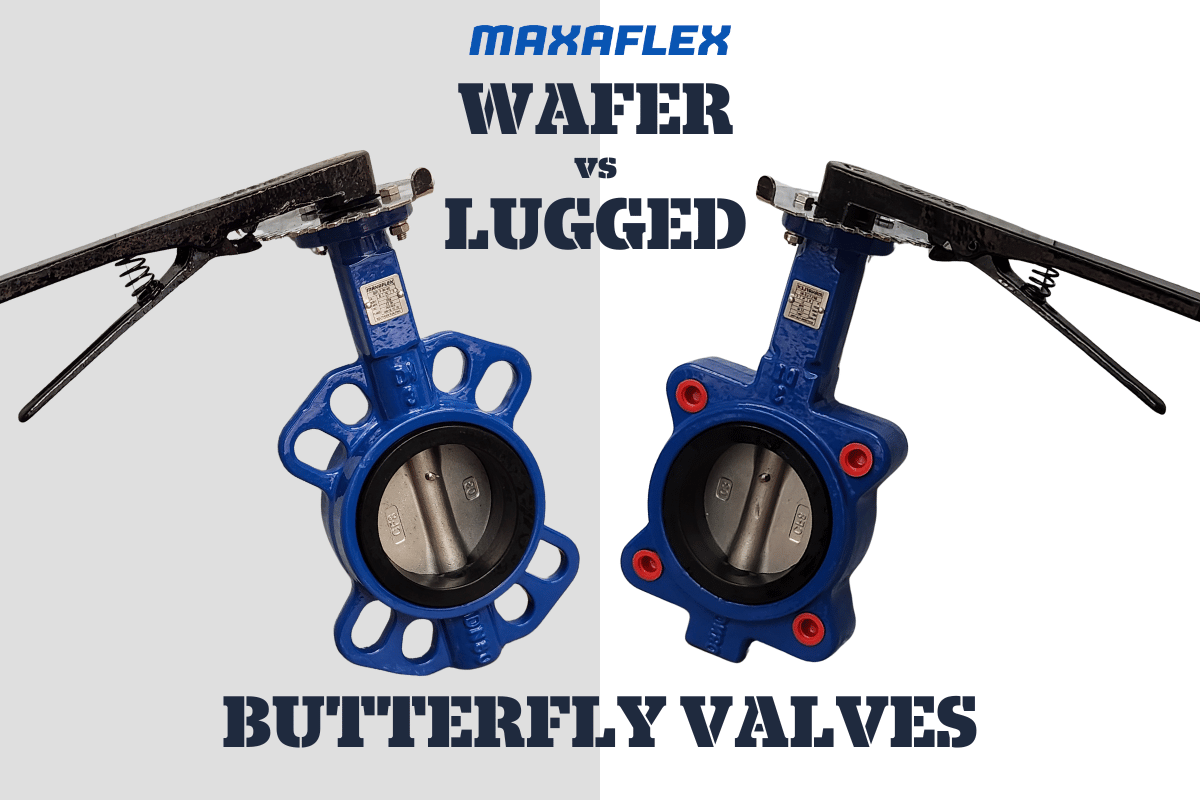

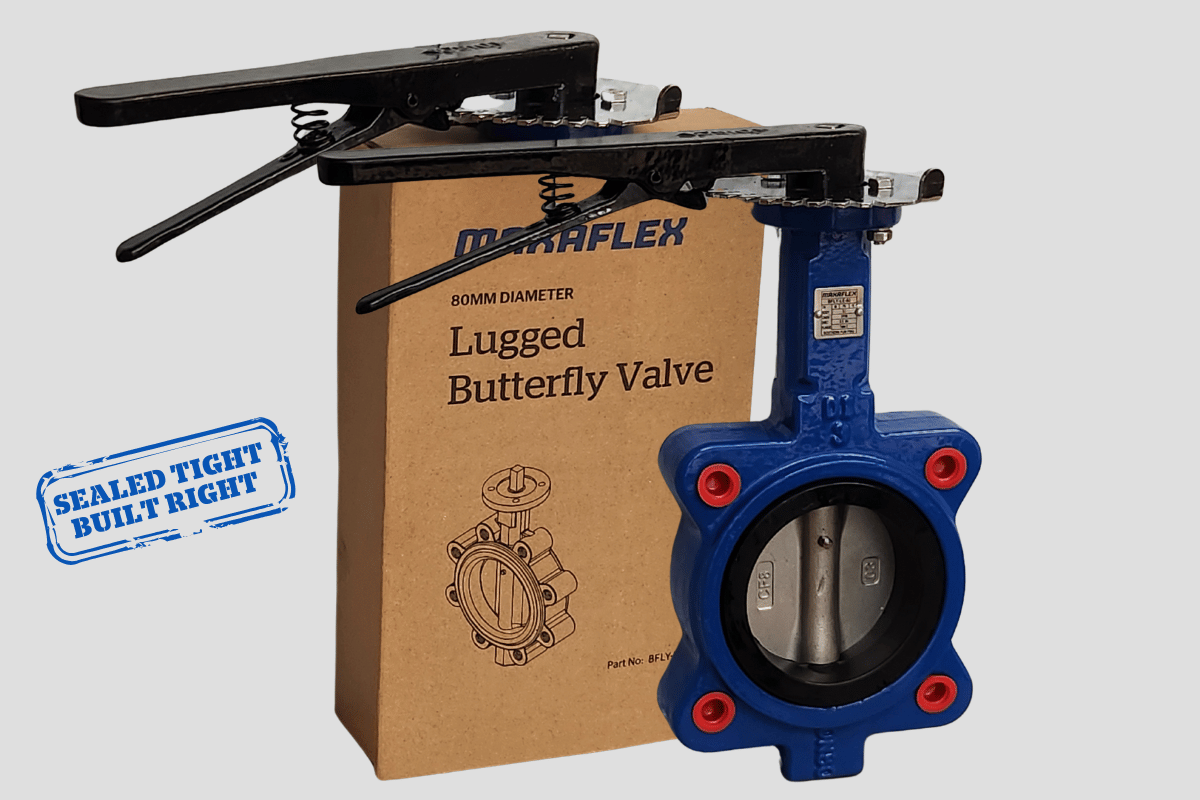

What is a Lugged Butterfly Valve?

A lugged butterfly valve has threaded inserts (or "lugs") that allow it to be bolted directly to pipe flanges. One of its biggest advantages is that it can be used for dead-end service, meaning you can install it at the end of a pipeline without needing additional support from a second flange.

Key Benefits of a Lugged Butterfly Valve:

- Easier maintenance – You can remove one side of the pipeline without disrupting the other.

- Stronger & more durable – Ideal for high-pressure applications.

- Versatile installation – Works as an end-of-line valve when needed.

- Better support – More robust due to its bolted connection.

Since lugged valves require more material for their design, they tend to be heavier and slightly more expensive than wafer valves. However, their strength and reliability make them a great choice for industrial applications, where high-pressure handling and isolation are necessary.

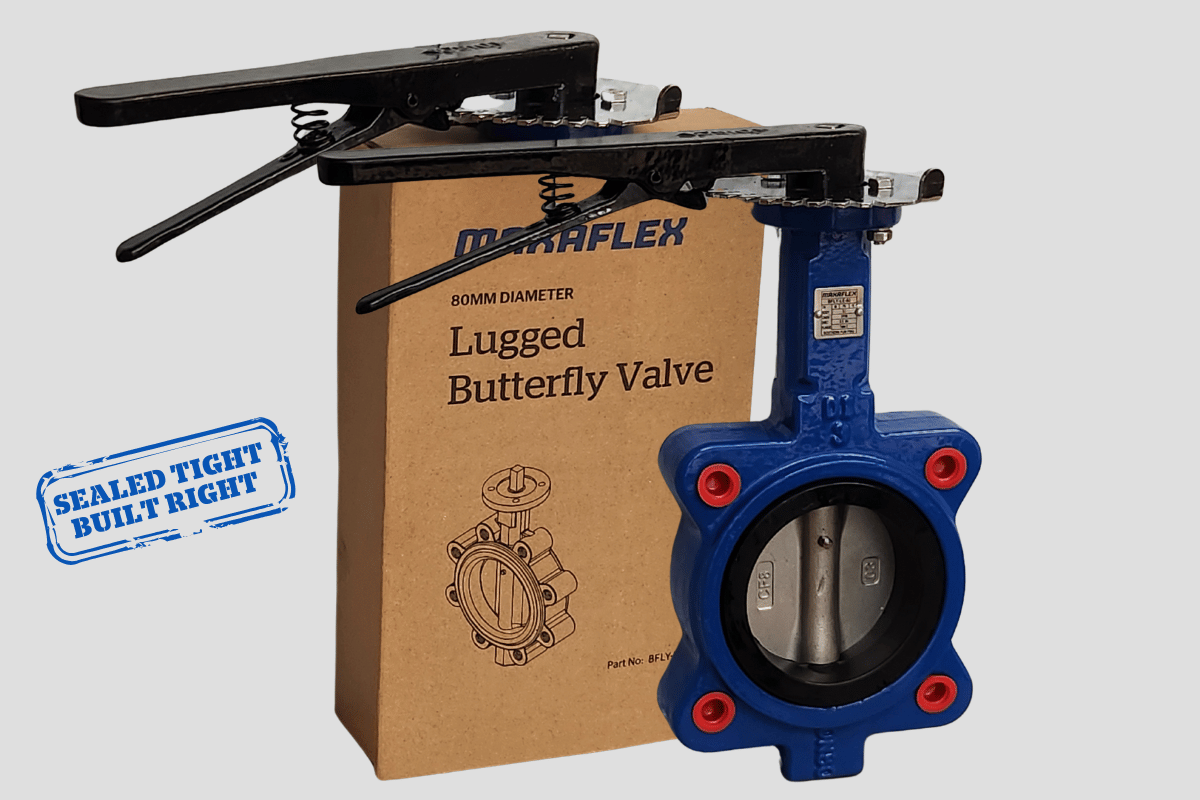

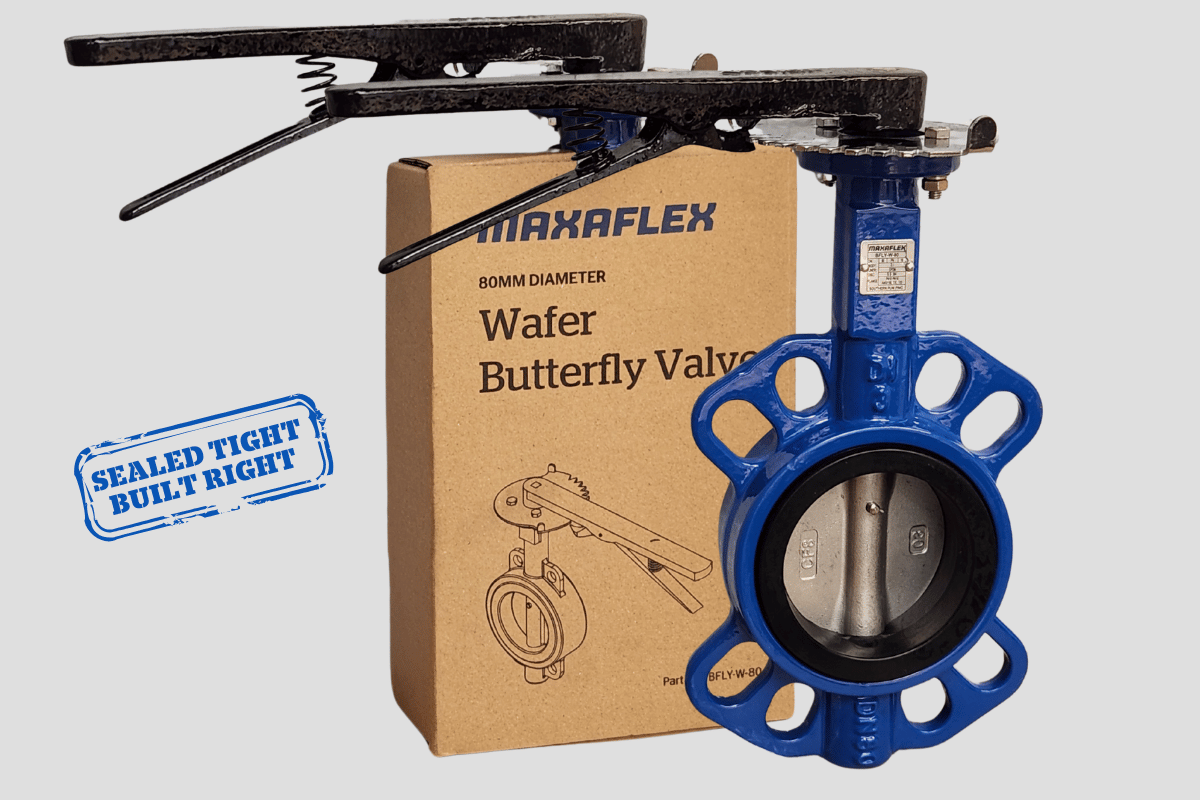

What is a Wafer Butterfly Valve?

A wafer butterfly valve is designed to be sandwiched between two pipe flanges. Unlike a lugged valve, it doesn’t have bolt holes—it relies on the flanges and bolts around it to stay in place. This makes it lighter, more compact, and more affordable than a lugged valve.

Key Benefits of a Wafer Butterfly Valve:

- More cost-effective – Requires less material, making it a budget-friendly choice.

- Lighter and more compact – Easier to handle and install.

- Ideal for moderate-pressure applications – Works well for general flow control.

The main drawback of a wafer valve is that you can’t remove one side of the pipeline without disconnecting the other, making maintenance a bit more involved. However, if you need a reliable valve for water treatment, HVAC systems, or processing plants, a wafer butterfly valve is an excellent choice.

Which Valve Should You Choose?

Go with a lugged butterfly valve if:

- You need a valve that can handle higher pressure and heavy-duty applications.

- You want the ability to remove one section of the pipeline without affecting the rest of the system.

- Your system requires a stronger, more durable valve for industrial use.

Choose a wafer butterfly valve if:

- You’re looking for a lightweight, cost-effective solution.

- You need a valve for general flow control in lower-pressure systems.

- Your system doesn’t require the extra strength of a lugged valve.

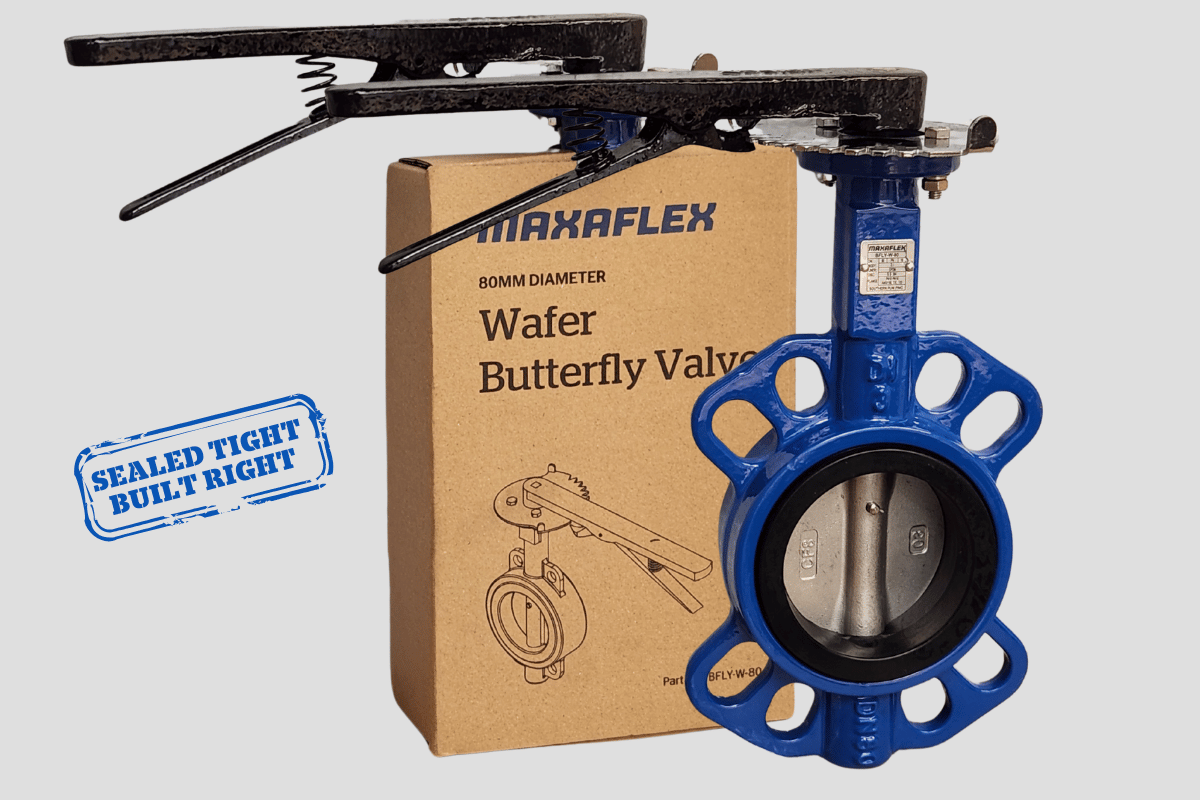

Maxaflex Has You Covered!

Both Maxaflex lugged and wafer butterfly valves are designed for durability and performance, featuring:

- Ductile iron bodies for extra strength

- 304 stainless steel discs for corrosion resistance

- EPDM rubber linings for excellent sealing

- 16-bar pressure rating to handle a variety of applications

Still unsure which one is right for you? Contact us today—our team is ready to help you find the perfect valve for your system!