Keeping Slurry Pumps in Peak Condition—Without the Manufacturer Wait Times

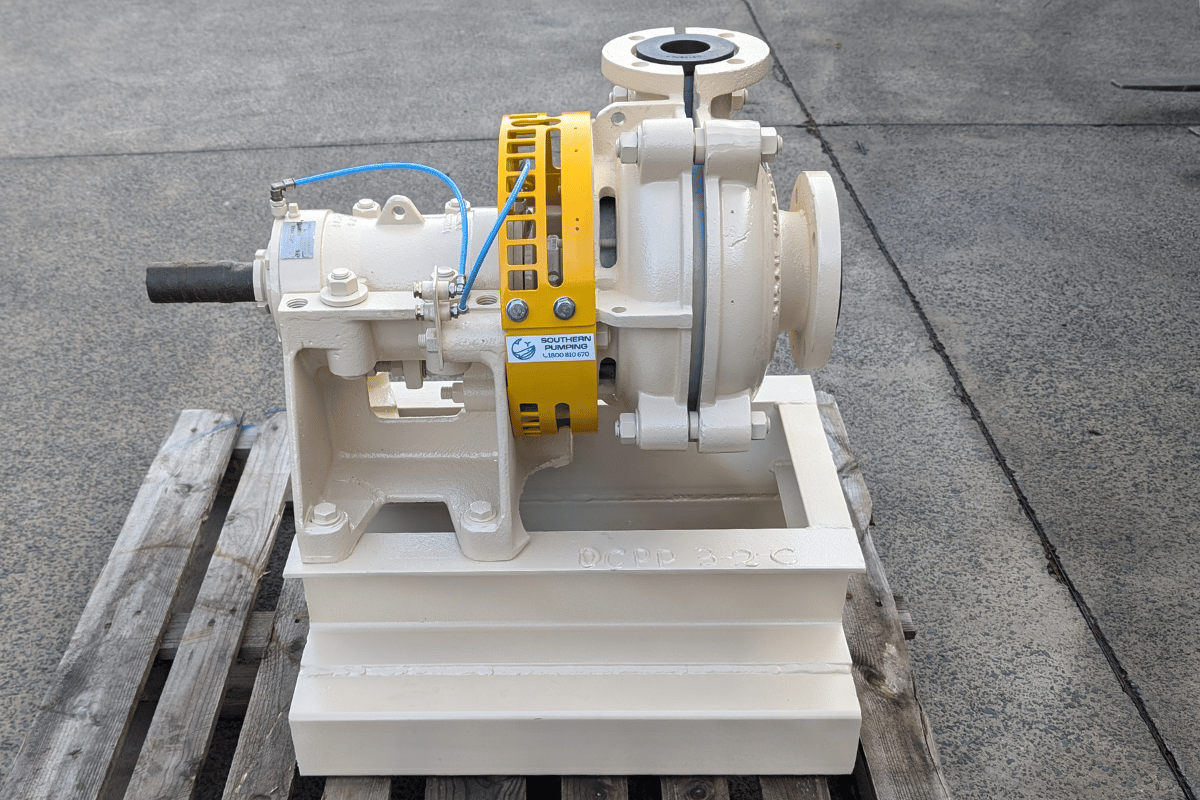

When a slurry pump from a mining client mine arrived at Southern Pumping for an overhaul, we knew exactly what to expect—heavy wear, signs of abrasive duty, and the usual battle scars from pumping tough slurries. But instead of a long, expensive wait for manufacturer servicing, our team stepped up to provide a timely and budget-friendly solution.

After stripping the pump down, our inspection revealed extensive wear on the wet-end components—impeller, volute liner, and frame plate liner—all showing heavy abrasion. We also noticed localized damage suggesting possible cavitation issues, which, if left unaddressed, could lead to premature failures in the future.

Beyond wear and tear, some modifications had been made to the pump’s gland follower, adding an extra Teflon flinger. Our job wasn’t just to replace worn parts—it was to rebuild the pump to perform at its best for the long haul.

Southern Pumping doesn’t just swap out components; we take a meticulous approach to pump overhauls. Here’s what we did:

Rather than sending the pump back to the manufacturer—where it could sit in a queue for months—a mining client chose Southern Pumping for a fast, expert overhaul. Our in-house workshop is equipped to handle slurry pumps of all sizes, delivering:

When it comes to keeping your pumps running, Southern Pumping offers a reliable alternative to lengthy manufacturer servicing. We bring the expertise, the facilities, and the hands-on approach to get your pumps back in action—quickly and efficiently.

Need a pump overhaul? Skip the wait and talk to our team today!

Call us on (02) 4271 2220

email us here or complete the order form below