Benefits to Southern Pumping's Customers from Investing in Equipment and People

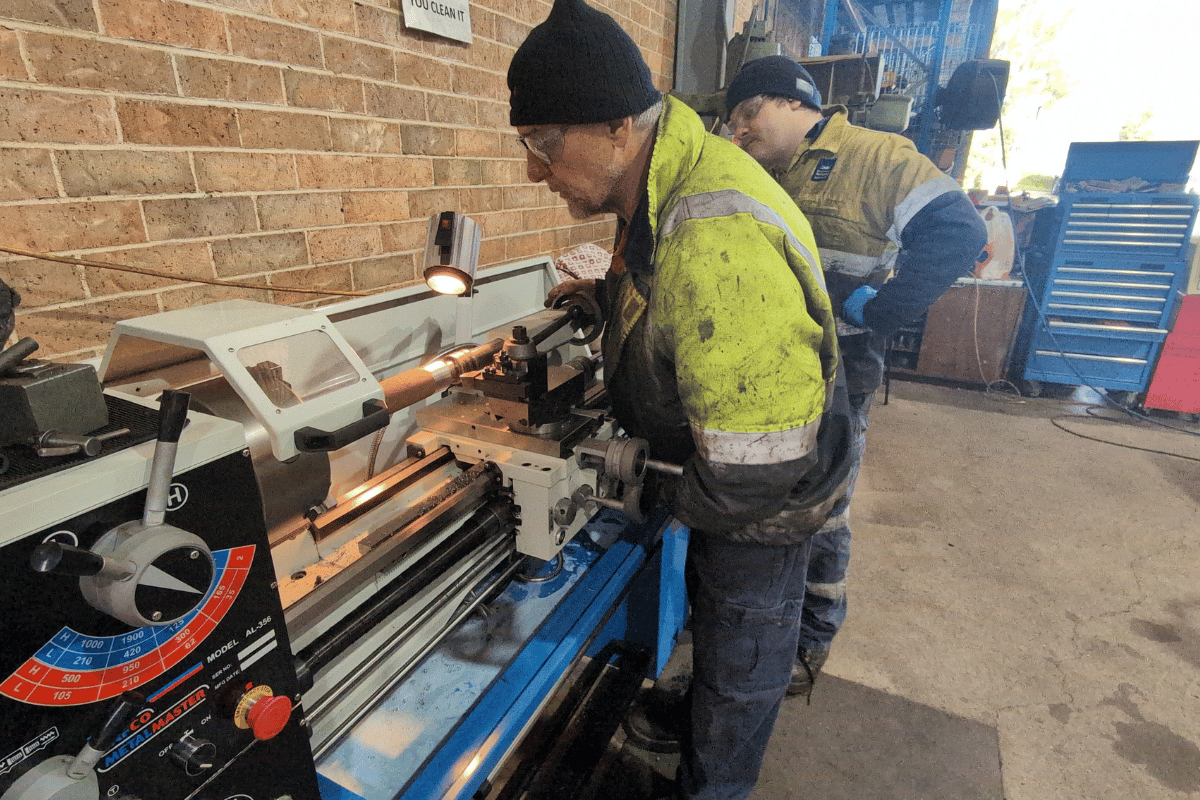

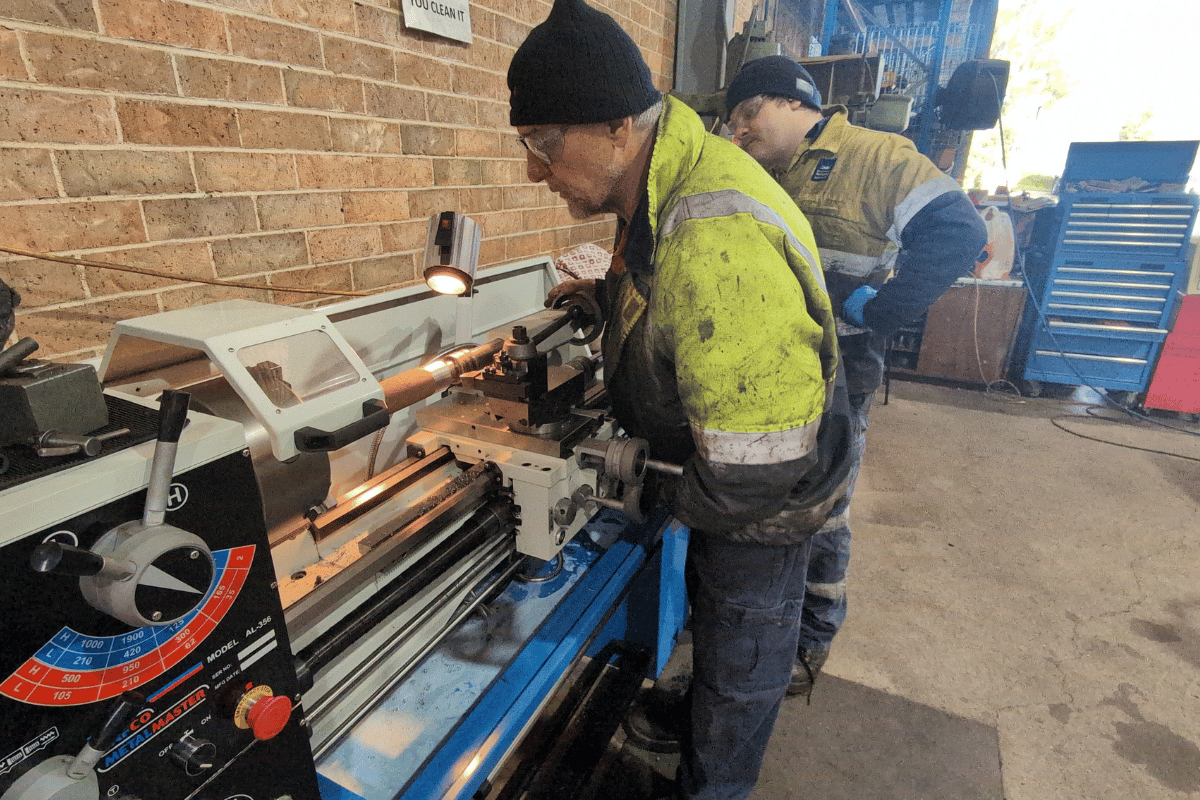

Southern Pumping is committed to delivering top-tier products and services to our customers. One of the most effective ways to achieve this is through strategic investments in both our equipment and our people. Upgrading from a manual belt-run WW2 era Le Blond lathe to the new L564E lathe, with advanced features such as the ability to drop the bottom out for machining large parts like impellers, exemplifies our commitment to quality and innovation. Here’s how these investments translate into benefits for our customers:

Modern lathes with advanced capabilities enable us to produce parts with greater precision and accuracy. This means our customers receive products that meet the highest standards of quality, with tighter tolerances and superior finishes. The L564E lathe allows us to manufacture complex parts, such as large impellers, with exceptional precision, ensuring optimal performance and reliability.

Upgrading to the L564E lathe improves our operational efficiency, reducing production times and minimizing downtime. This increased efficiency allows us to complete projects more quickly, providing our customers with faster turnaround times without compromising on quality. Whether it's a custom-engineered pump set or a standard product, our customers can rely on us for timely delivery.

The ability to drop the bottom out of the new lathe for machining large parts like impellers enhances our capacity to handle a wider range of projects. Southern Pumping's onsite workshop facilities enable us to custom-engineer pump sets to suit any application. This flexibility means we can cater to the unique requirements of each customer, delivering tailored solutions that precisely meet their needs.

Investing in advanced equipment goes hand-in-hand with investing in our people. Training and upskilling our team members on the latest technology ensure they are equipped with the knowledge and expertise to leverage the full potential of the new lathe. This combination of cutting-edge equipment and skilled personnel fosters a culture of innovation, allowing us to continually improve our products and services. Additionally, the introduction of new equipment promotes knowledge transfer between team members, as experienced staff guide others in mastering the new technology.

The introduction of new equipment often presents new challenges, which our team addresses through collaborative problem-solving. This collaborative approach enhances our ability to develop innovative solutions to complex problems, directly benefiting our customers. Our team's expertise, combined with the capabilities of the new lathe, ensures that we can tackle even the most demanding projects with confidence. The process of solving these new challenges also facilitates the transfer of knowledge, as team members share their insights and techniques.

The implementation of new equipment necessitates the development and documentation of new best practices and protocols. By systematically documenting these practices, we ensure consistent quality in our production processes. This consistency means that our customers can trust in the reliability and performance of every product we deliver.

At Southern Pumping, we are dedicated to continuous improvement. Investing in advanced equipment and the ongoing development of our team reflects our commitment to staying at the forefront of industry standards. Our customers benefit from this commitment through access to the latest technology and the assurance that we are always striving to enhance our products and services.

Our decision to upgrade to a new centre lathe was based on the fact that our existing machine was outdated and potentially losing accuracy. The constraints we had when selecting the right lathe included:

The L564E lathe met all these criteria, ensuring that we can maintain high standards of precision and efficiency in our production processes.

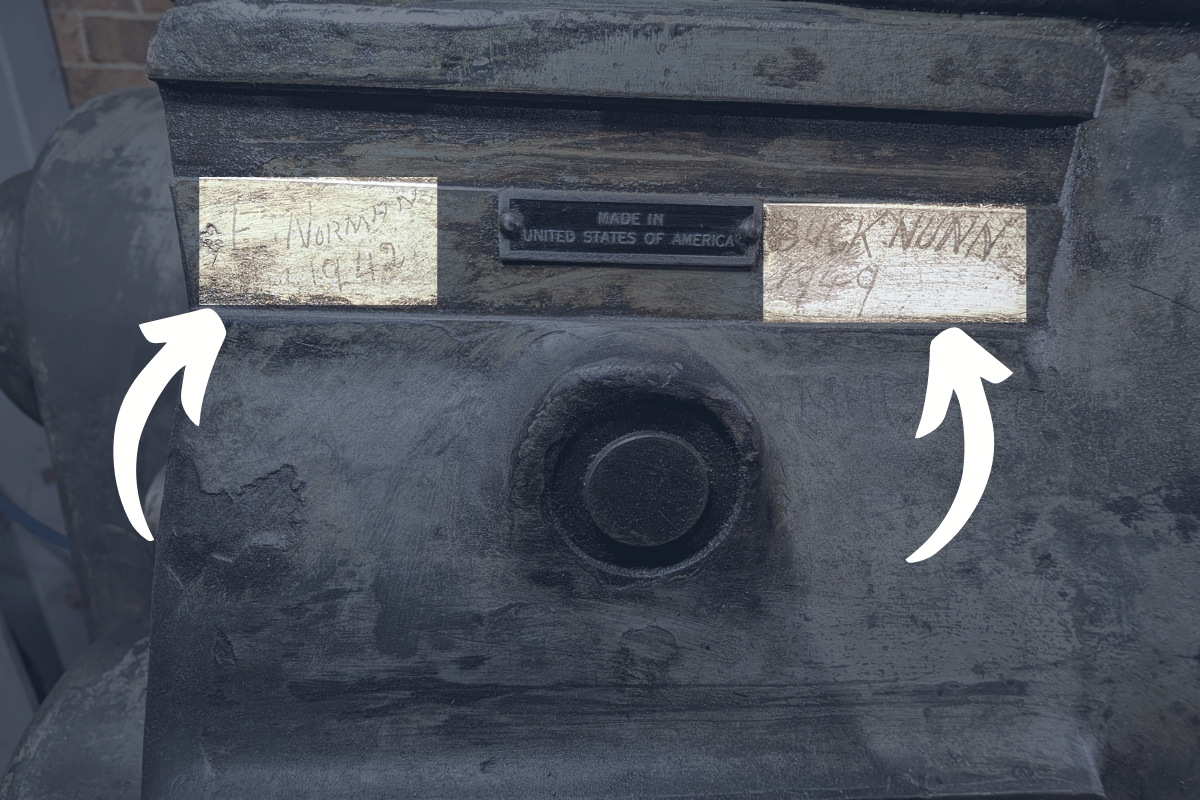

While we value our team, we won’t be letting them tag the new lathe like E. Norman in 1942 and Buck Nunn in 1949!

Southern Pumping’s investment in upgrading from a manual belt-run WW2 era Le Blond lathe to the modern, accurate L564E lathe with advanced features is a testament to our dedication to quality and customer satisfaction. By enhancing product quality, increasing efficiency, offering greater customization, fostering expertise and innovation, promoting collaborative problem-solving, ensuring consistent quality, and committing to continuous improvement, we deliver significant benefits to our customers. Our strategic investments in equipment and people ensure that Southern Pumping remains a trusted partner for all your pump set needs, capable of providing the highest level of service and quality in every project. The introduction of new equipment not only boosts our operational capabilities but also facilitates the continuous transfer of knowledge within our team, ensuring that our expertise grows alongside our technological advancements.

Call us on (02) 4271 2220

email us here or complete the order form below