Heavy-Duty Slurry Pumps: A Comprehensive Guide

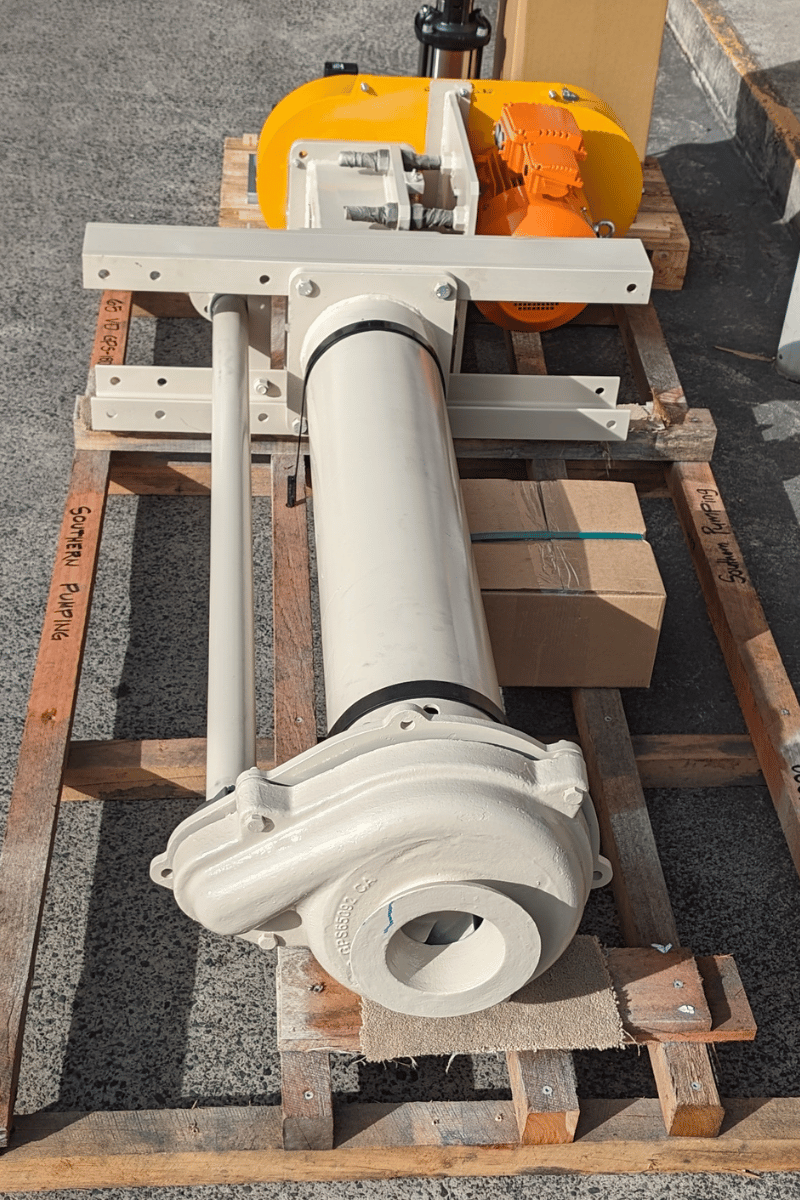

In industries that rely on the efficient handling of abrasive and corrosive materials, heavy-duty slurry pumps are the unsung heroes that keep operations running smoothly. Whether it's mining, wastewater treatment, or chemical processing, these pumps are essential for moving solids-laden slurries with ease. But mastering the power and efficiency of these pumps requires a comprehensive understanding of their inner workings and practical applications. Southern Pumping proudly supplies and services leading slurry pump brands, ensuring access to reliable, high-performance equipment that meets your specific needs.

In this guide, we delve into the intricacies of heavy-duty slurry pumps and unlock the secrets to maximizing their performance. From the fundamentals of slurry pump design to the selection criteria for different applications, we leave no stone unturned in providing actionable insights. Southern Pumping's extensive experience with slurry pump systems enables us to guide you toward the best solutions, ensuring optimal pump performance and efficiency.

Our goal is to equip industry professionals, engineers, and operation managers with the knowledge they need to make informed decisions when it comes to selecting, operating, and maintaining heavy-duty slurry pumps. We’ll also explore emerging trends and technologies shaping the future of slurry pump systems, and how Southern Pumping stays ahead by partnering with the best brands in the industry.

Slurry pumps play a crucial role in a wide range of industrial processes, from mining and mineral processing to wastewater treatment and chemical processing. These heavy-duty pumps are designed to handle abrasive, corrosive, and solids-laden fluids with unparalleled efficiency and reliability. Southern Pumping, as a trusted supplier, ensures that our clients have access to the most advanced and durable slurry pump models to handle these demanding environments.

For instance, the mining industry heavily relies on slurry pumps to transport ore-bearing slurries from the mine site to processing plants. Southern Pumping partners with top manufacturers to offer pumps that handle high solids content and harsh operating conditions, ensuring steady material flow for further processing. Similarly, in wastewater treatment, our pumps are instrumental in moving sludge, a byproduct of the treatment process, for further processing or disposal.

Southern Pumping’s can provide high-quality slurry pumps for the chemical processing industry, designed to transport abrasive and corrosive materials, such as catalysts, pigments, and specialty chemicals, with minimal maintenance and downtime. Across these industries, Southern Pumping’s comprehensive range of slurry pumps keeps industrial processes flowing seamlessly.

Southern Pumping offers the supply of a wide range of slurry pumps, each tailored to specific industrial applications. Understanding the different types of slurry pumps is essential for selecting the most appropriate solution, and with Southern Pumping’s expert support, you can make the best choice for your needs.

One of the most common types is the centrifugal slurry pump, which utilizes centrifugal force to move the slurry. Southern Pumping supplies centrifugal slurry pumps known for their high efficiency and ability to handle various slurry compositions. Positive displacement pumps, which are better suited for handling highly viscous or abrasive slurries, are also available through Southern Pumping, offering consistent flow even under demanding conditions.

Whether you need submersible, high-pressure, or multistage slurry pumps, Southern Pumping’s extensive catalogue covers all the specialized variants, ensuring you find the perfect solution for your operational requirements.

Southern Pumping offers the supply of a comprehensive range of slurry pump services designed to enhance performance and extend the lifespan of your equipment. Our expertise includes rubber lining, which provides superior abrasion resistance in harsh environments, and epoxy and ceramic coatings that offer protection against corrosion and wear.

We specialize in custom-engineered parts and fittings to meet specific operational requirements, including tailored flush lines for stationary bearings to improve lubrication and reduce maintenance.

Additionally, our sandblasting services prepare surfaces for coating or repair, while structural reinforcements ensure pump housings can withstand the rigors of demanding industrial applications. With these services, Southern Pumping ensures your slurry pumps are optimized for peak performance and durability.

Choosing the right slurry pump is critical for operational success, and Southern Pumping is here to guide you through the selection process. Key factors such as slurry characteristics, flow rate, pressure requirements, and operating environment must all be considered. With Southern Pumping’s expertise, you can be confident that your chosen pump will meet your operational needs and provide long-term, reliable performance.

We help our clients assess their requirements in terms of energy efficiency, maintenance, and life-cycle costs, ensuring they invest in a slurry pump solution that is both cost-effective and tailored to their unique operational environment.

Proper installation and regular maintenance are vital for maximizing the performance and lifespan of heavy-duty slurry pumps. Southern Pumping offers full-service support, including installation assistance and ongoing maintenance programs, to ensure your pumps operate at peak efficiency.

Our team follows best practices to ensure pumps are properly aligned, securely mounted, and connected to the system. Southern Pumping’s maintenance services, including regular inspections and preventive repairs, keep your pumps running smoothly, while our expert technicians address common issues like cavitation and vibration to minimize downtime.

In the world of industrial operations, slurry pumps are essential to maintaining efficiency and reliability. Southern Pumping not only supplies industry-leading slurry pumps but also provides the expertise needed to select, install, and maintain them. With our comprehensive support, industry professionals can harness the full power and efficiency of heavy-duty slurry pumps, ensuring smooth operations and long-term performance.

Call us on (02) 4271 2220

email us here or complete the order form below