Ensuring Performance and Reliability: Overhauling and Testing Goulds Centrifugal Pumps

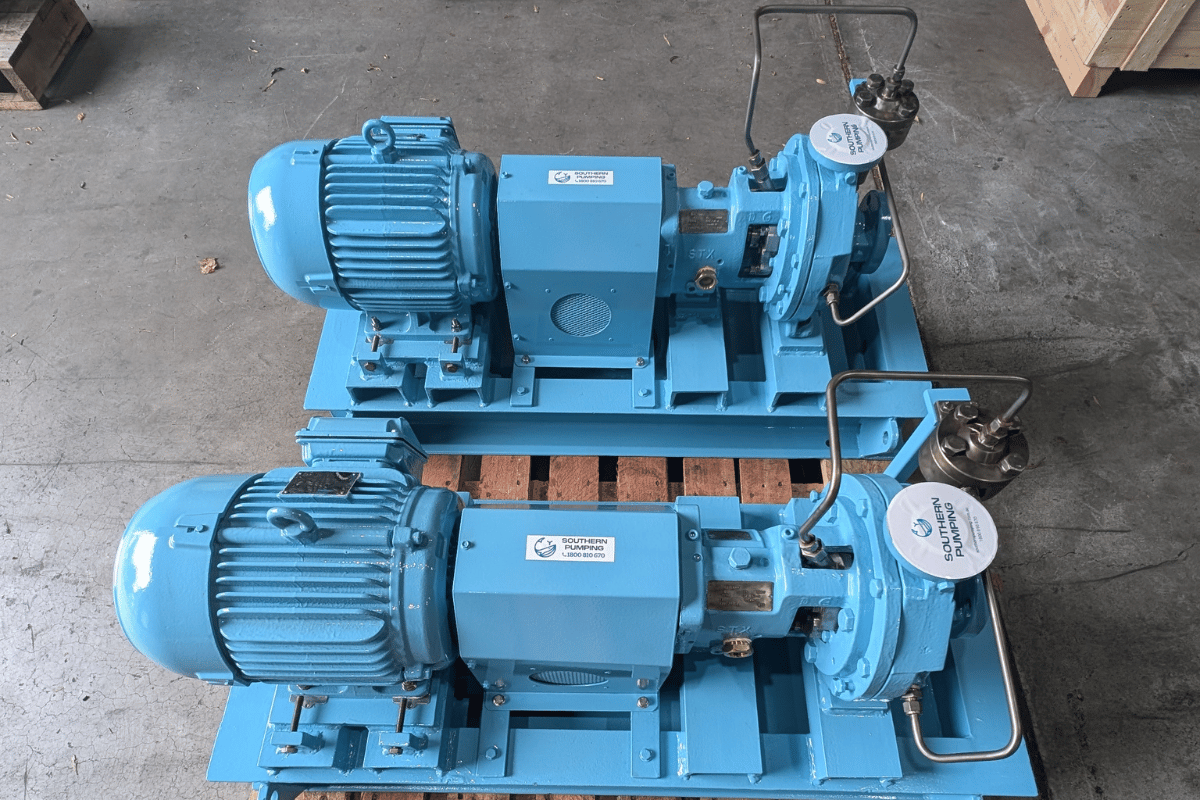

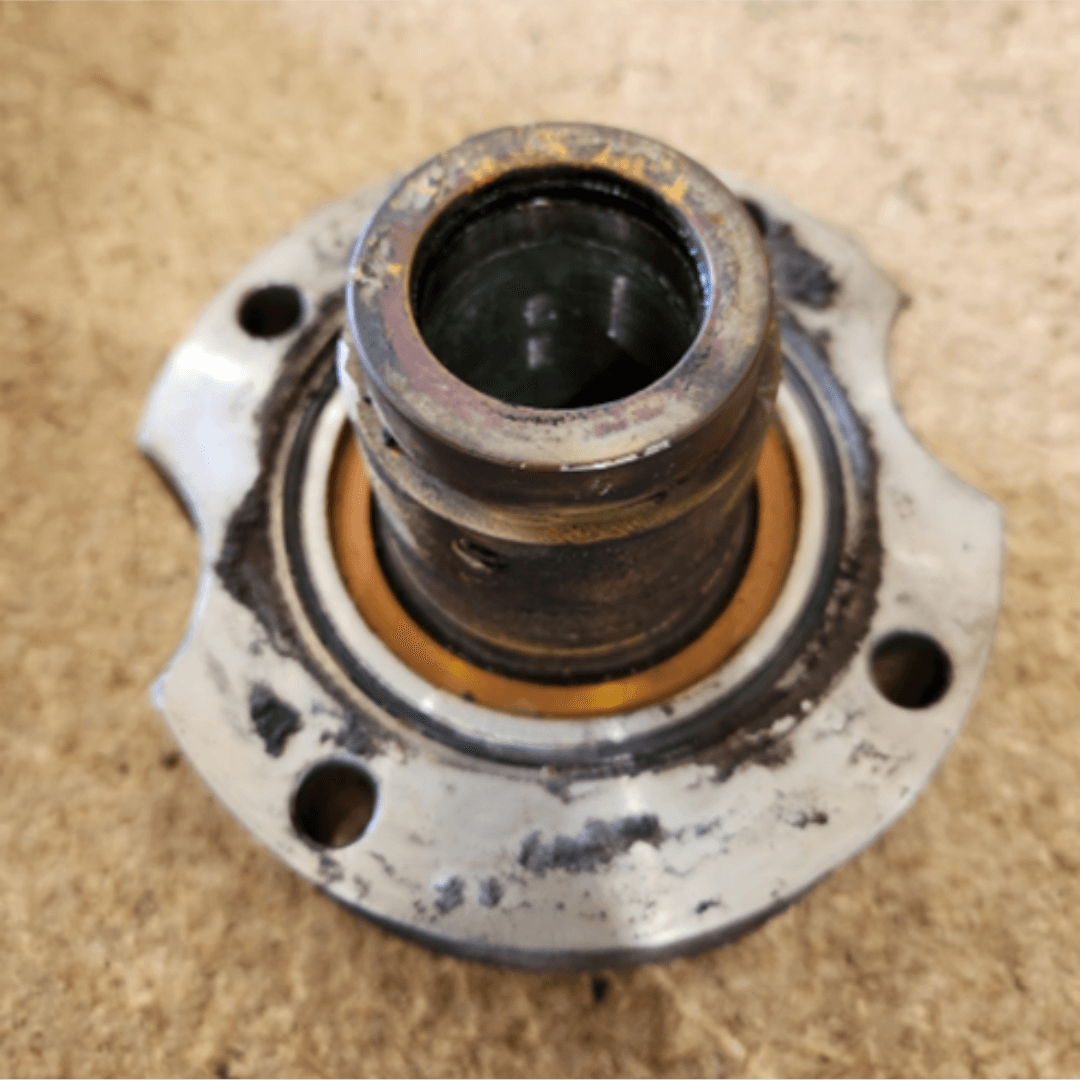

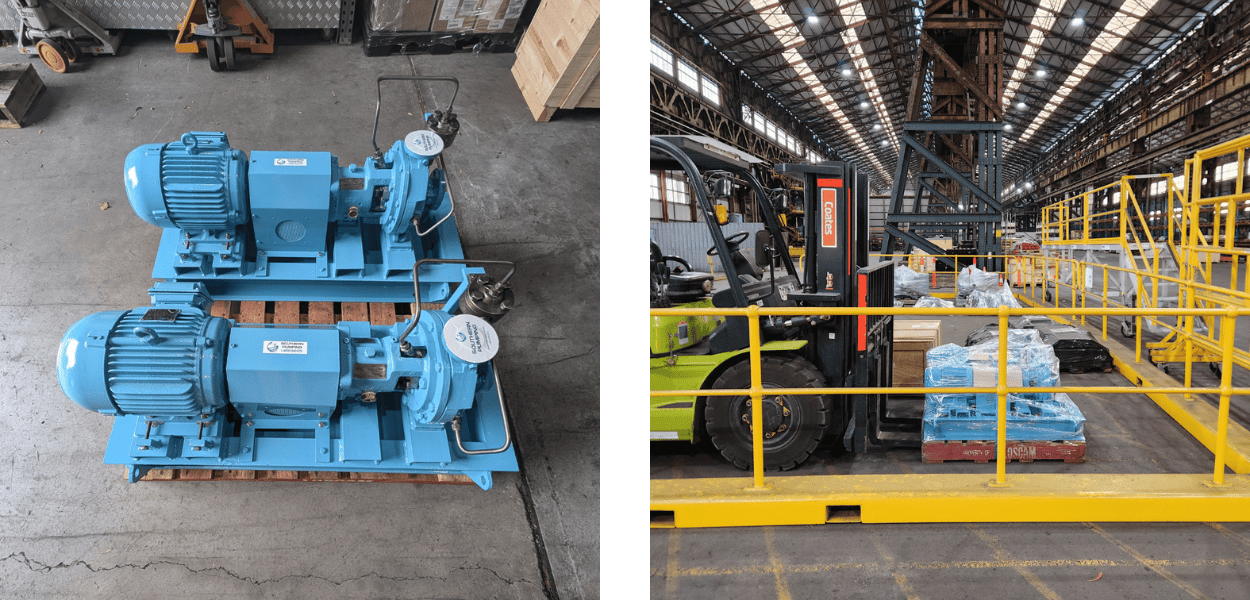

At Southern Pumping, ensuring the reliability and longevity of pumping equipment is at the core of what we do. Recently, two Goulds centrifugal pumps (Model: 1X1.50-8) underwent a comprehensive overhaul and rigorous testing process. This article outlines the inspection findings, repair recommendations, and the results of the hydrostatic and dynamic performance tests that validated the pumps' operational excellence.

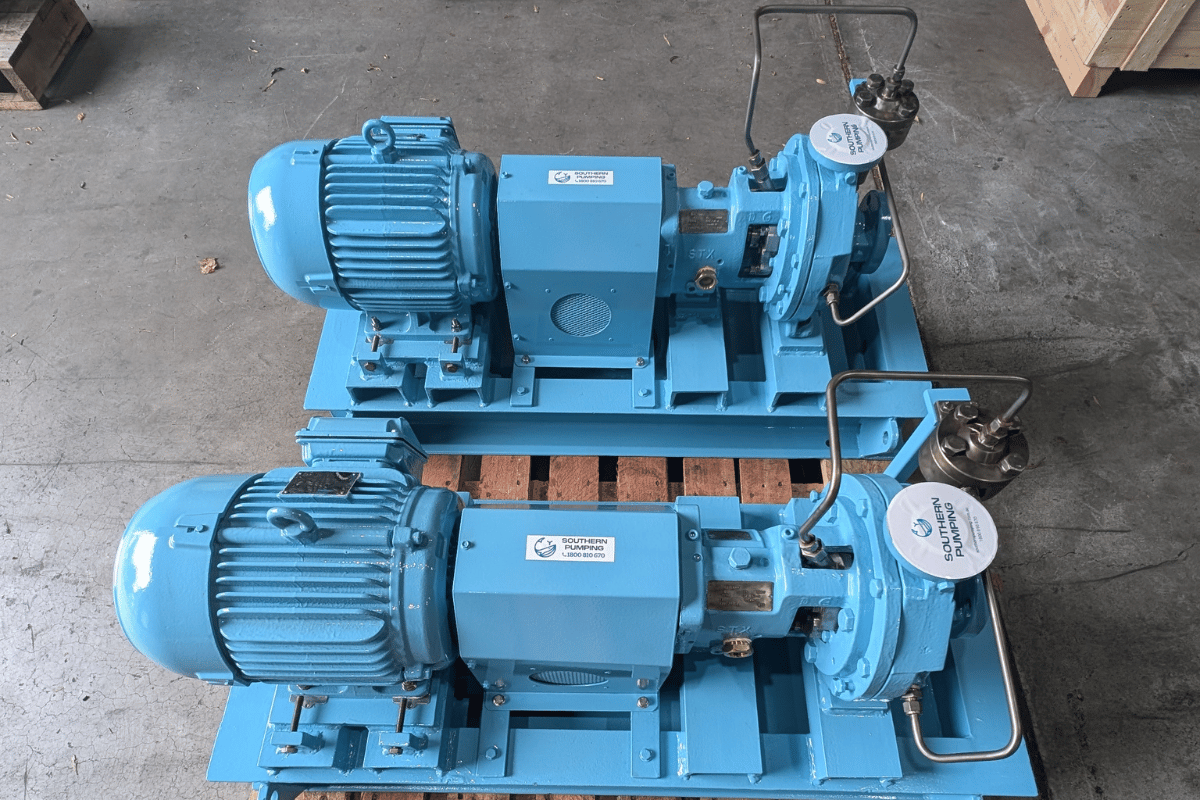

Upon arrival at Southern Pumping, the two pumps were in need of an overhaul. A visual inspection revealed significant grease, dust, and grit build-up across the pump assemblies. Despite the contamination, initial checks showed the shafts, casings, and impellers to be in good condition—a promising start.

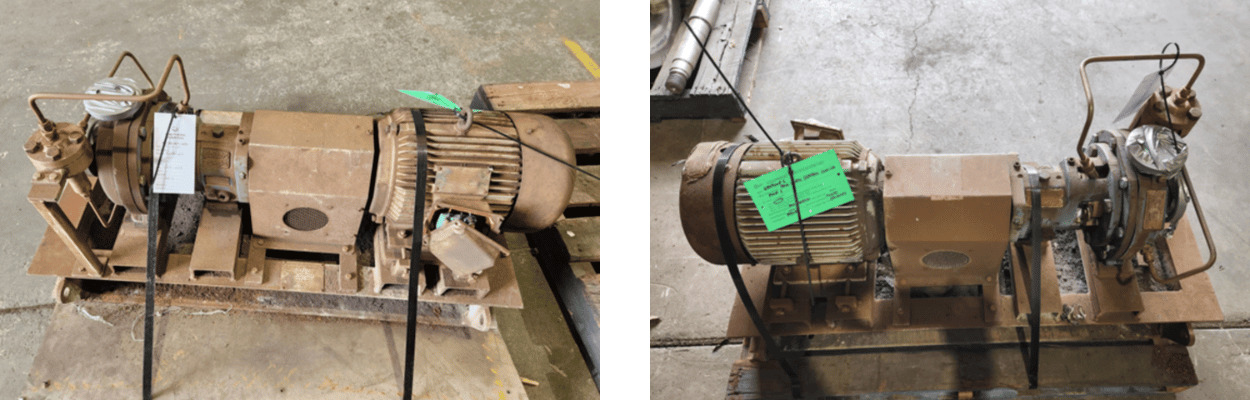

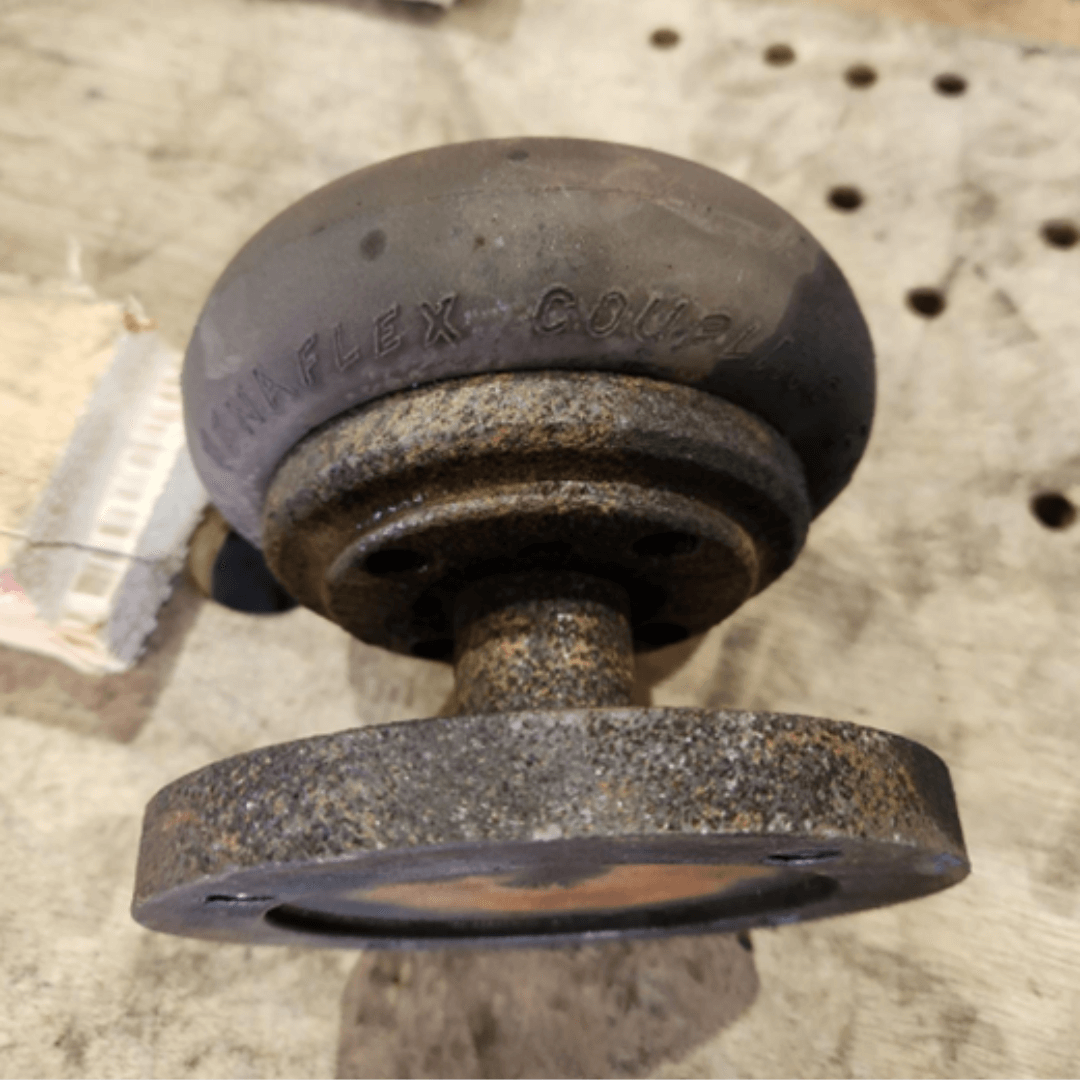

Our inspection process involved disassembly, cleaning, and evaluation of all major components. The findings were as follows:

Based on the inspection findings, our team implemented the following recommendations:

With these refurbishments complete, both pumps were reassembled and prepared for testing to validate their performance under operational conditions.

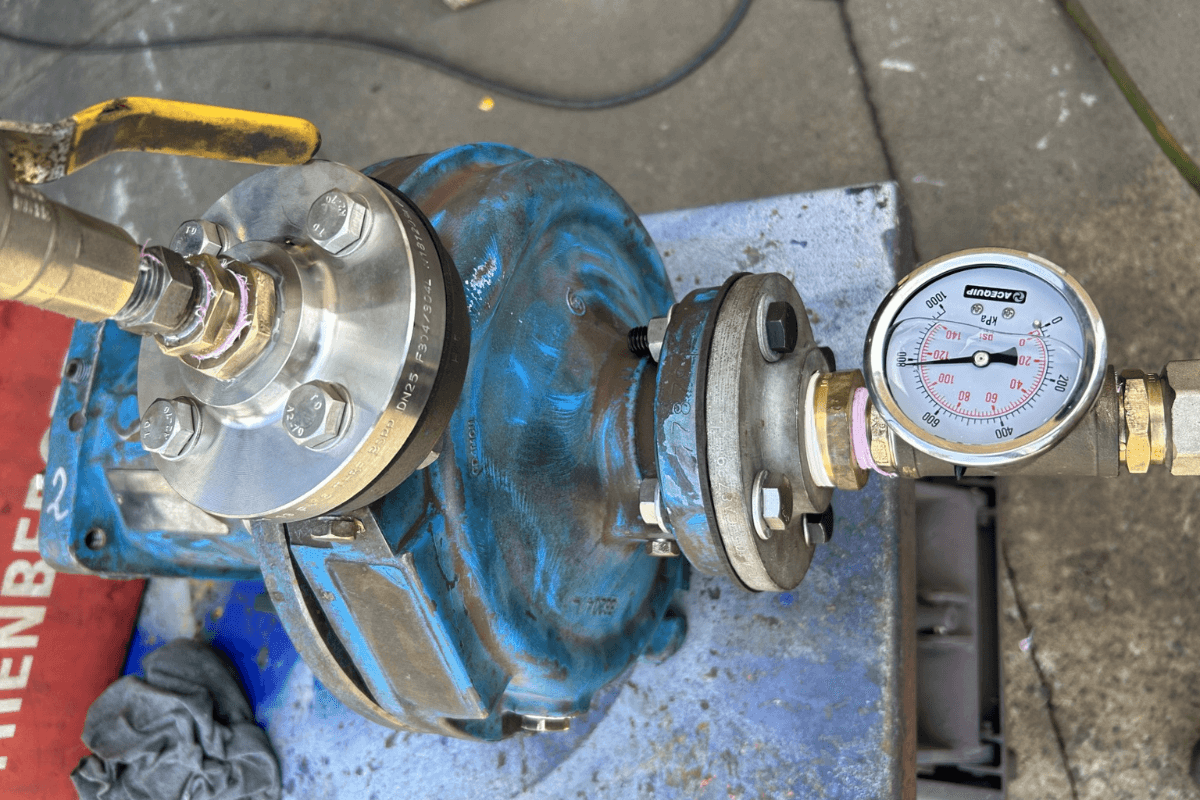

Hydrostatic Testing: Proving Structural Integrity

Each pump was subjected to a hydrostatic test at a pressure of 840 kPa using a Rothenberger Test Bucket. This test ensures that the pump casing and seals can withstand operational pressures without leaks.

| Pump Serial No. | Test Pressure | Result |

| 7780791.1 | 840 kPa | Pass |

| 7780791.2 | 840 kPa | Pass |

|

|

Both pumps passed this critical test, confirming their structural integrity and readiness for service.

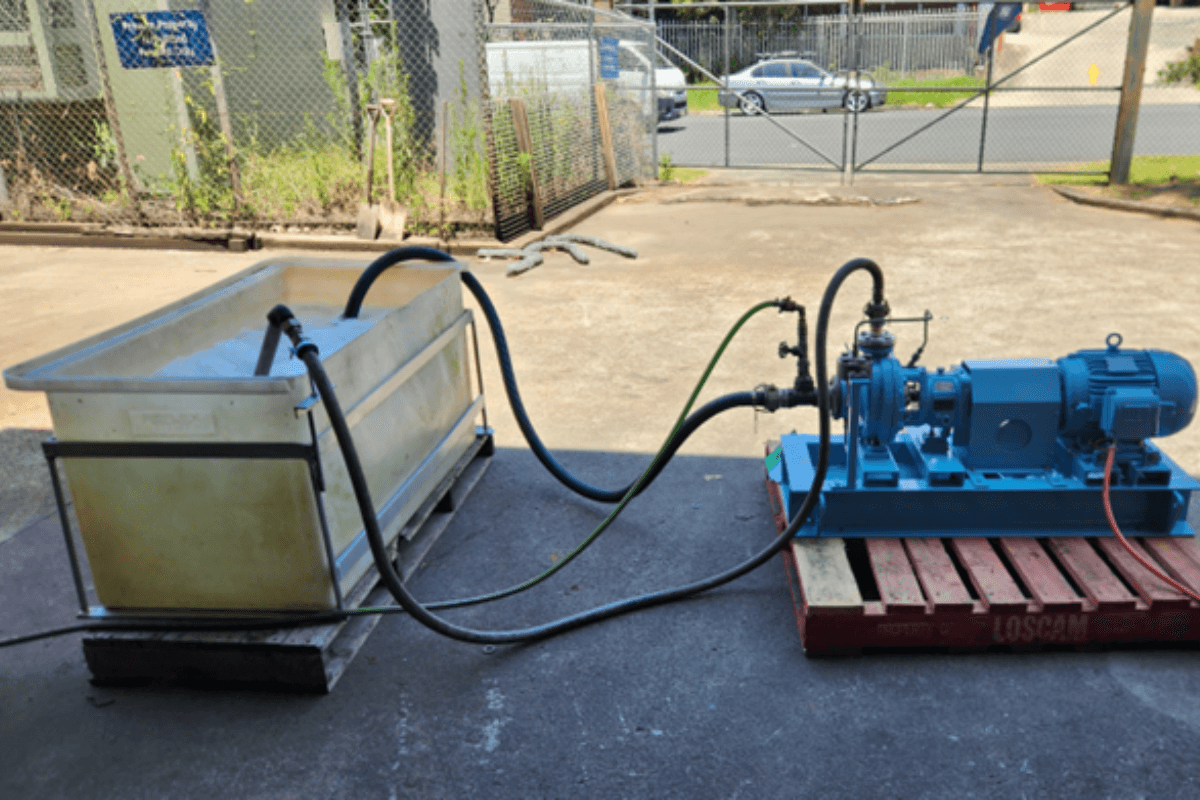

To verify operational performance, each pump was subjected to a 2-hour dynamic test, during which bearing temperatures were closely monitored. Results showed steady temperature increases that remained well within acceptable operating limits:

Pump 1 (Serial No. 7780791.1)

| Time |

Pump Bearing Temp (°C) |

Motor Bearing Temp (°C) |

| 9:00 AM |

66.0 | 58.8 |

| 9:30 AM |

66.7 | 61.3 |

| 9:50 AM |

67.0 | 62.0 |

Pump 2 (Serial No. 7780791.2)

| Time |

Pump Bearing Temp (°C) |

Motor Bearing Temp (°C) |

| 11:45 AM |

31.5 | 30.1 |

| 12:45 PM |

67.0 | 59.0 |

| 1:25 PM |

60.4 | 60.4 |

The stable temperature readings indicated excellent bearing performance and efficient operation across both pumps, especially given the tests were conducted on one of the hottest days of the year with a high ambient temperature.

With the overhaul and testing process complete, both pumps demonstrated exceptional structural integrity and operational performance. The replacement of key components, including bearings, seals, and gaskets, has restored these pumps to like-new condition, ensuring reliability for future service.

This case highlights the importance of thorough inspection, proper overhaul practices, and rigorous testing. By following these processes, Southern Pumping continues to deliver pumps that meet the demanding performance and longevity expectations of our clients.

Call us on (02) 4271 2220

email us here or complete the order form below