Unlock the Power: Exploring the Synergy Between Cam Locks and Progressive Cavity Pumps

In the world of fluid transfer systems, two components come together to form an unbeatable duo: cam locks and progressive cavity pumps. These dynamic technologies work in perfect synergy, offering unparalleled efficiency and effectiveness across various industries. Whether it's in agriculture, manufacturing, or oil and gas, understanding the power of this combination can revolutionize your operations.

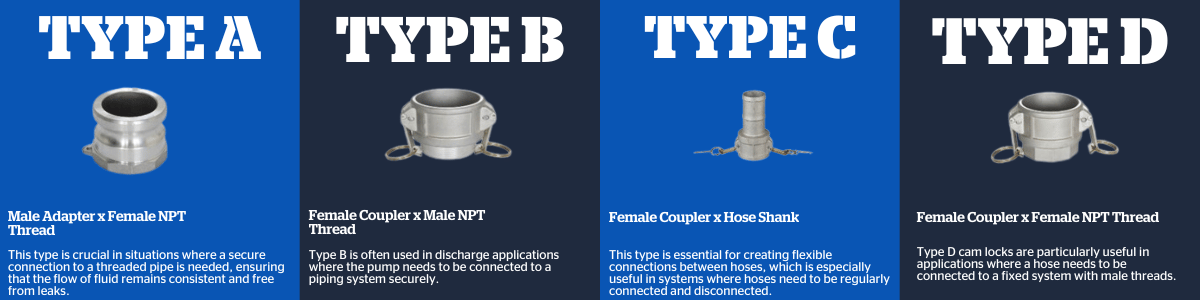

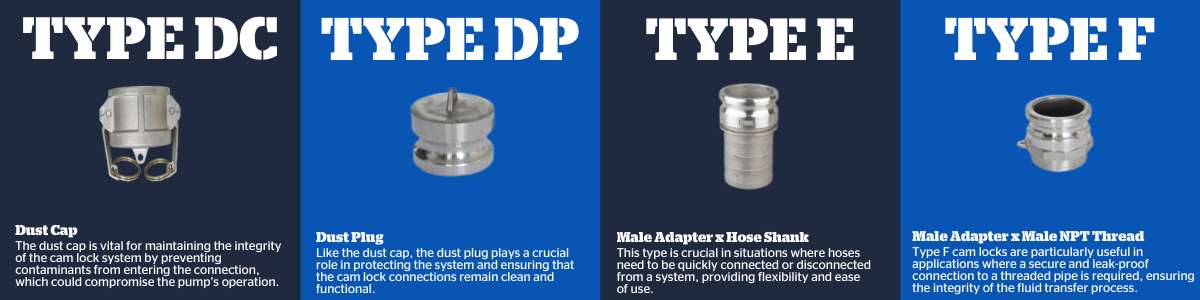

Cam locks, with their quick-connect feature, allow for easy and secure connections between hoses, pipes, and other fluid transfer equipment. They provide a leak-free solution, saving time and resources while ensuring safety. On the other hand, progressive cavity pumps excel in handling viscous and abrasive fluids, offering precise flow control and improved performance.

By harnessing the combined power of cam locks and progressive cavity pumps, businesses can optimize their fluid transfer processes, enhance productivity, and minimize downtime. Furthermore, the compatibility and versatility of these two components make them suitable for a wide range of applications.

Cam locks are a type of quick-connect coupling widely used in fluid transfer systems. They are designed to provide a secure and leak-proof connection between hoses, pipes, and other fluid-handling equipment. The key feature of cam locks is their ability to quickly and easily attach and detach, allowing for fast and efficient fluid transfer.

At the heart of a cam lock is a series of cam-shaped locking mechanisms that grip the mating part, such as a hose or pipe. When the two components are pushed together, the cams engage and lock the connection in place. To disconnect, the user simply needs to pull back on the cam lock's collar, which disengages the locking mechanism and allows the components to be separated.

Cam locks come in a variety of sizes, materials, and configurations to suit different applications. They can be made from durable metals like brass, stainless steel, or aluminum, or from engineered plastics for lighter-duty uses. The choice of material depends on the specific requirements of the fluid transfer system, such as the pressure, temperature, and chemical compatibility of the fluids being handled.

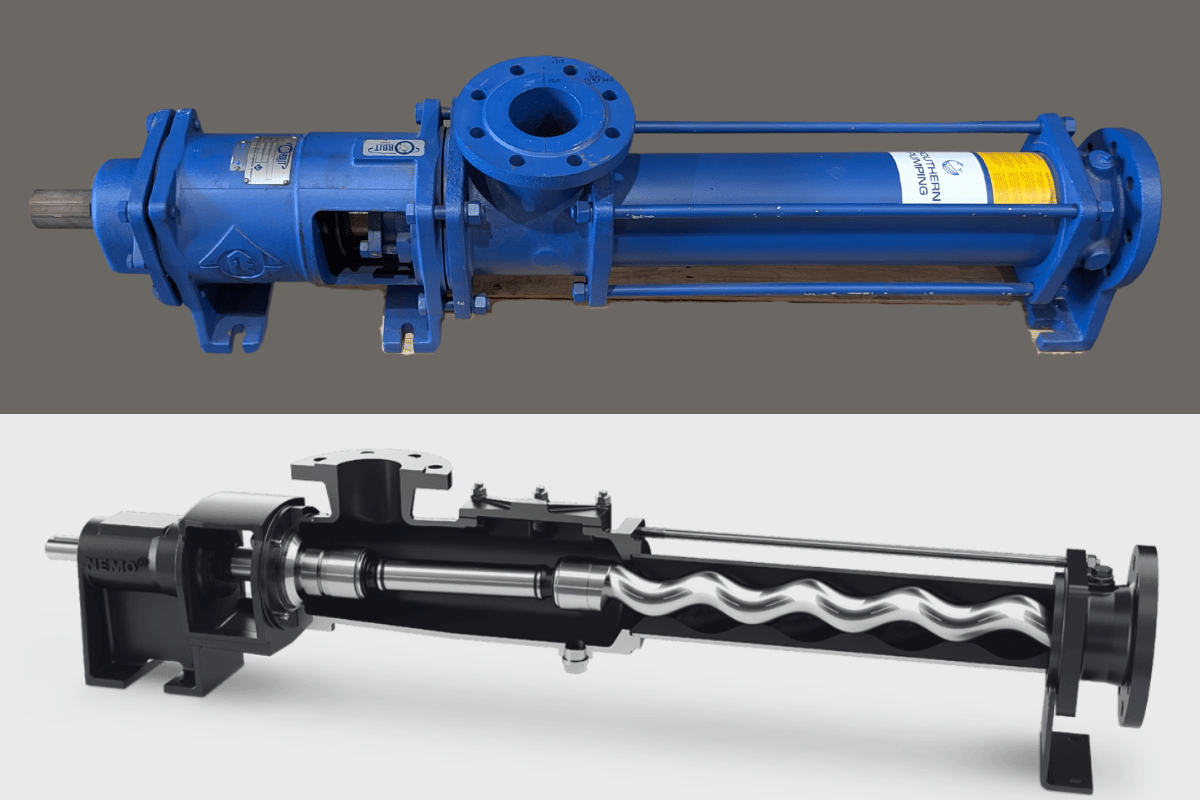

Progressive cavity pumps, also known as eccentric screw pumps, are a unique type of positive displacement pump that excels at handling viscous and abrasive fluids. These pumps use a helical rotor and a matching stator to create a series of sealed cavities that move the fluid from the inlet to the outlet.

As the rotor turns eccentrically within the stator, the cavities increase in size at the inlet, drawing in the fluid, and then decrease in size at the outlet, pushing the fluid out. This continuous, smooth flow of the fluid is a key advantage of progressive cavity pumps, as it allows for precise control and metering of the fluid flow.

One of the standout features of progressive cavity pumps is their ability to handle a wide range of fluid types, including highly viscous, shear-sensitive, and even abrasive materials. This makes them ideal for use in industries such as oil and gas, mining, food processing, and wastewater treatment, where traditional pump technologies may struggle to perform effectively.

The combination of cam locks and progressive cavity pumps offers a range of benefits that can significantly improve the efficiency and performance of fluid transfer systems. By leveraging the strengths of both components, users can experience enhanced productivity, reduced maintenance, and improved safety.

One of the primary advantages is the ease of connection and disconnection provided by cam locks. The quick-connect feature allows for rapid fluid transfer, reducing downtime and increasing overall productivity. This is particularly beneficial in applications where frequent connection and disconnection of hoses or pipes are required, such as in mobile or temporary fluid transfer applications.

Furthermore, the secure and leak-proof nature of cam lock connections helps to maintain the integrity of the fluid transfer system, preventing costly spills and minimizing the risk of environmental contamination. This is especially important when handling hazardous or sensitive fluids, where leaks can have significant consequences.

When selecting cam locks for progressive cavity pumps, material choice plays a significant role in performance and durability. Aluminum cam locks are often preferred over polypropylene (poly) cam locks due to their superior strength and resistance to wear and tear. Aluminum offers better durability in high-pressure applications and is less prone to damage from impact or harsh environmental conditions, making it a more reliable choice for industrial use. In contrast, polypropylene cam locks, while lighter and more corrosion-resistant, may not withstand the same level of stress and are more suited for lower-pressure applications.

The synergy between cam locks and progressive cavity pumps extends beyond just the ease of connection. Cam locks can also contribute to the overall efficiency and performance of the progressive cavity pump.

One way in which cam locks enhance the efficiency of progressive cavity pumps is by ensuring a consistent and stable fluid flow. The leak-free connections provided by cam locks help to minimize turbulence and pressure fluctuations in the fluid transfer system, allowing the progressive cavity pump to operate at its optimal performance level.

Additionally, the quick-connect feature of cam locks can simplify the maintenance and servicing of the progressive cavity pump. By enabling rapid disconnection and reconnection of the pump from the fluid transfer system, cam locks make it easier to access and service the pump components, reducing downtime and improving overall equipment reliability.

Southern Pumping has made the strategic decision to discontinue its range of cam locks to better focus on our specialized product offerings. This decision allows us to concentrate our resources on developing and enhancing the products that best serve our core market of pumping solutions. While cam locks are important components in many fluid handling systems, our commitment is to delivering the highest quality and most innovative solutions within our specialized areas. For customers requiring cam locks, we are happy to refer you to one of our trusted national partners who can meet all your cam lock needs.

First though, we need to clear our existing stock. To do so we are having a run-out sale on all cam locks in stock with a massive 65% of the entire range while stocks last.

The synergy between cam locks and progressive cavity pumps is a powerful combination that can unlock new levels of efficiency, productivity, and safety in a wide range of fluid transfer applications. By leveraging the strengths of these two complementary technologies, businesses can streamline their operations, reduce maintenance and downtime, and ensure the reliable and secure transfer of even the most challenging fluids.

As we've explored in this article, the advantages of using cam locks with progressive cavity pumps are manifold, from the ease of connection and disconnection to the enhanced performance and integrity of the fluid transfer system. By carefully selecting the right cam locks and progressive cavity pumps for their specific needs, and maintaining them with diligence, industry professionals can unlock the full potential of this powerful partnership.

Looking ahead, the continued evolution and innovation in both cam locks and progressive cavity pumps promise even greater advancements in the future. As new materials, designs, and smart technologies emerge, the synergistic possibilities between these two components will only continue to expand, offering even more opportunities for businesses to optimize their fluid transfer operations and stay ahead of the curve.

Call us on (02) 4271 2220

email us here or complete the order form below